Disc Stack Separation Technology is in our DNA

Disc Stack Separation Technology, also known as conical plate centrifuge, is a well-proven technology invented over 100 years ago, using centrifugal force for removing solids, (mainly contaminants) from liquids, liquids from liquids, and solids from gas.

A technology for various applications

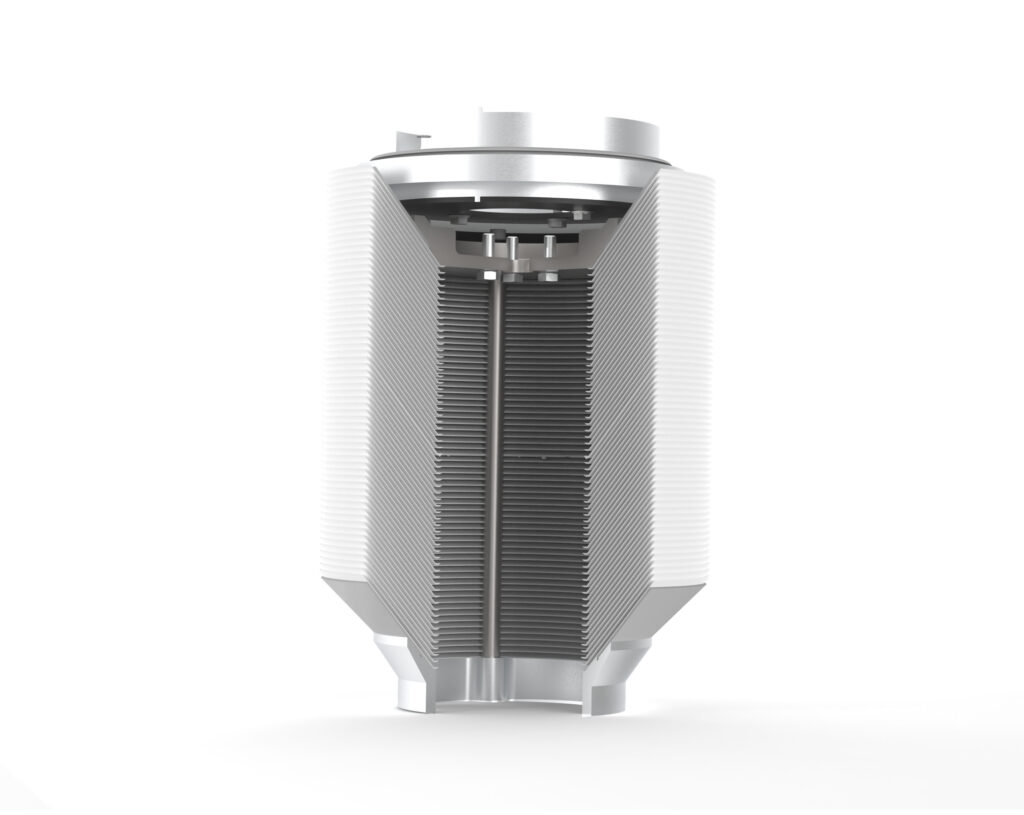

The technology consists of a rotor with a series of conical discs stacked onto each other, rotating inside a stationary housing. Due to the rotation, the contaminated gas is vented into the rotor chamber and is forced through the gap between the conical discs. Using inclined discs, particles then settle onto the disc, where inclination also allows particles to slide downwards when exposed to extreme centrifugal forces. As they travel down towards the edge of the lamellas, the particles start to coalesce with each other to form larger droplets. The heavier these droplets become, the faster they move towards the edge of the disc. At this edge the gravitational force is at its highest, causing the particle to be thrown off and onto the inner wall of the rotor chamber. The particles then trickle down to the bottom, where the separated media is finally fed out.

The design and arrangement of the discs is custom-engineered for each application. The size of the discs determines the surface settling area, which varies depending on the particle load for your specific application. By controlling the rotation speed and flow rate, we can with great accuracy predict the limit particle size for separation, therefore enabling precise calculations of the separation efficiency.

One of the main advantages with Disc Stack Separation Technology is that it provides a high separation rate on a continuous level while requiring only minimal maintenance. Rotera disc stack separators are scalable, designed in a highly-compact format, and available for a wide range of application across multiple industries.

At Rotera, we use our competence in Disc Stack Separation Technology to design oil mist separators for various applications. This includes oil mist separators for compressors or vacuum pumps as well as Active Crankcase Ventilation Systems (ACCVS) for passenger cars, commercial vehicles, and off-highway machines.