Active Crankcase Ventilation Systems for Passenger Cars

Rotera’s Active Crankcase Ventilation (ACCV) Systems are based on our patented Disc Stack Separation Technology that continuously separates oil particles from blow-by gases. Our compact solutions for crankcase ventilation achieve separation efficiency close to 100% and are suited for all passenger car applications.

Rotera Disc Stack Technology

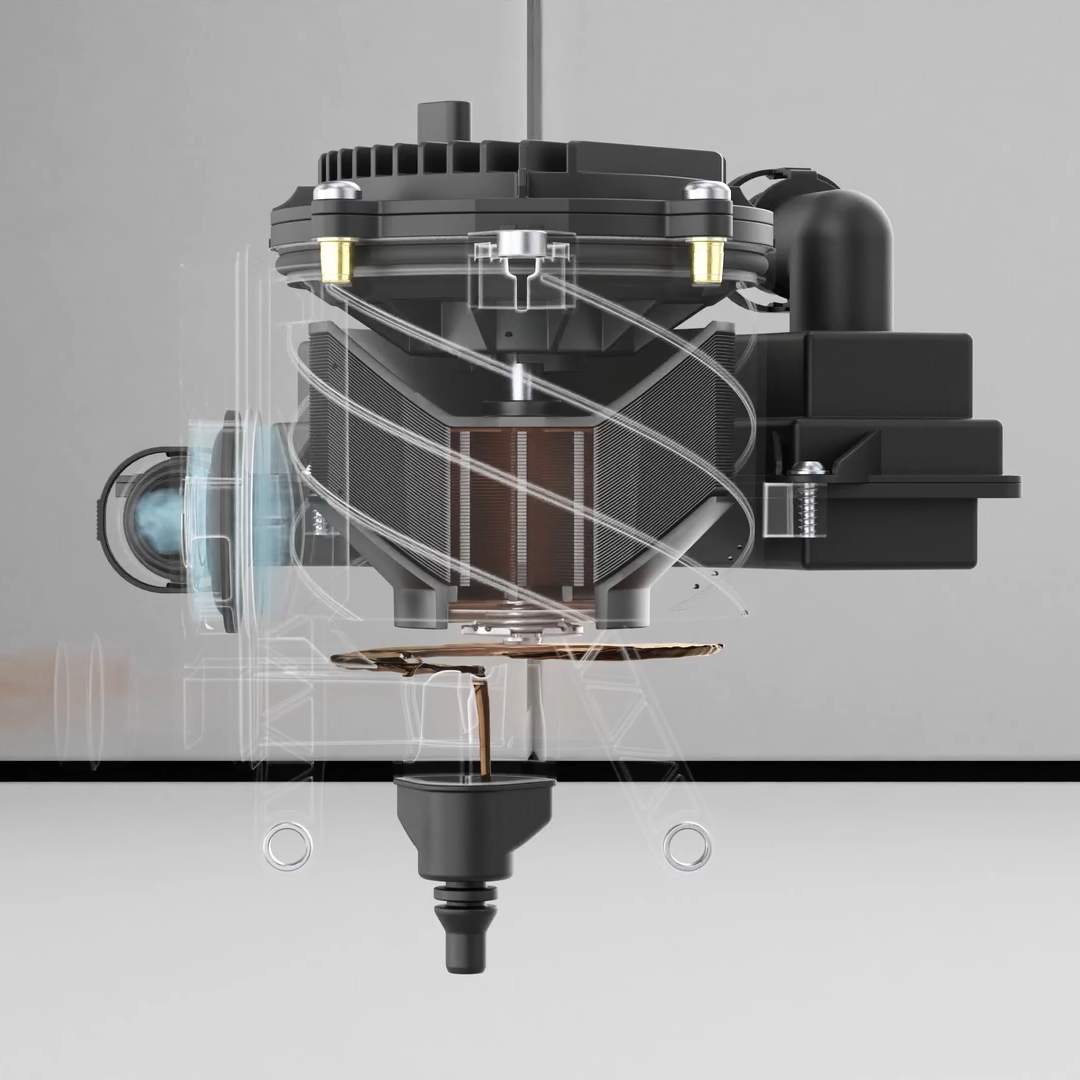

The technology consists of a rotor with conical discs stacked onto each other, which is driven either electrically or hydraulically. Blow-by gas gets pushed – and due to rotation also sucked – into the rotor and forced through the gaps between the single discs of the stack. Due to flow and centrifugal force, the captured particles move towards the surface of the next located rotating disc and coalesce with each other. The separated particles get forced to the outer edge of each disc and are ejected onto the inner wall of the rotor.

Clean gas is vented back to the engine intake manifold whereas the separated oil is fed back to the oil recirculation system. Perfectly adopted to the limited installation space on most light vehicle applications, the technology can also be designed into cam covers, functionally integrated into crankcases or attached to the engine where space permits.

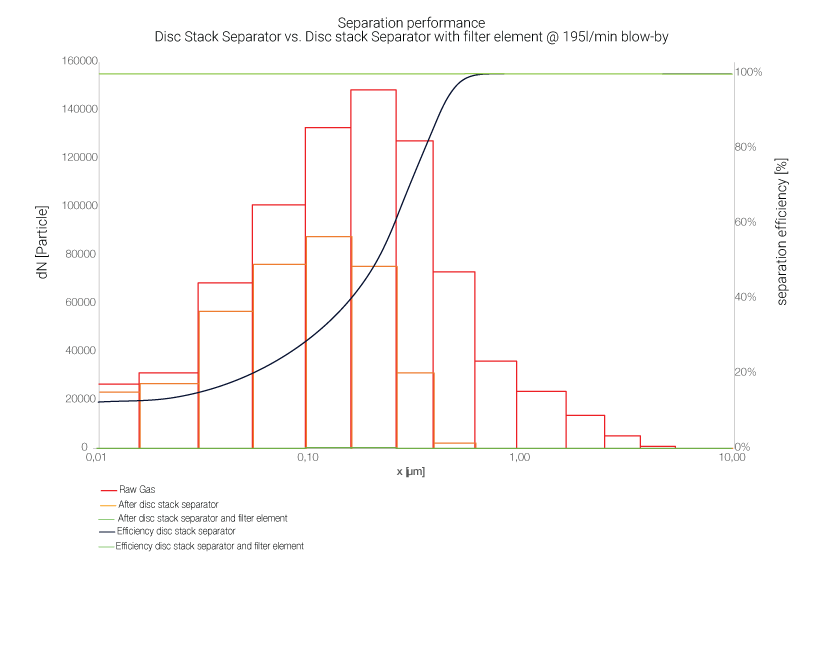

New Disc Stack Technology combined with filter element

Our Disc Stack Separation Technology provides one of the highest separation rates available today. To reach maximum efficiency rates, our newest patented innovation that combines Disc Stack Separation Technology with a highly efficient downstream filter ensures close to zero particle emissions where even most of the finest particles (<0.6μm) are removed. The solution is developed to support our global customers for compliance with stricter emission regulations adopted by commissions such as the European Commission and CARB.

The filter has regenerative properties and can discharge itself to some extent when the engine is off, thereby feeding the separated oil back into the oil circuit. The proprietary filter design is customer-specific and adapted to the installation space, composition of the blow-by gas, particle sizes, temperatures, and the desired service lifetime, among other custom requirements.

Drive Systems

The disc stack separators can be either driven by a BLDC motor or are moved hydraulically. The robust BLDC motor is designed as a lifetime component and includes electronics to communicate with the engine ECU. It can be powered by 12V or 24V and communicates preferentially via LIN, the standard for light vehicles. Our patented system for hydraulic drive HERON is based on the HERON turbine system with a contactless seal between the drive and rotor chamber. The system gets fed by engine oil from the oil circuit, which flows through the hollow drive axle, goes up to the turbine, and out through the radially located nozzle. When it passes through the nozzle, the disc stack separator starts to rotate because of the repulsion effect and can reach speeds up to 16,000 rpm.

Patented Guiding Ribs

To prevent separated oil particles from being accompanied by the purified gas out of the separator, Rotera developed and patented unique guiding ribs. In combination with the stream of the rotating gas inside the separation chamber, these ribs ensure that the separated oil droplets are moved down to the bottom of the rotor chamber where the oil is then ejected and channelled back to the engine oil circuit.

For all type of fuels

Engines and vehicle models have varying requirements for crankcase ventilation systems, which is why we offer customized designs, products, and solutions. Our systems for crankcase ventilation are designed for traditional combustion engines and can be adapted to e-fuel and hydrogen driven engines.

Rotera technology for your application

Connect with our product team to discuss your application.